| Type |

Definition |

Construction |

Operation Principle |

Components |

Applications |

| Lead-Acid Batteries |

Rechargeable battery with lead plates and sulfuric acid. |

Consists of lead plates and sulfuric acid in a plastic case. |

Energy stored via chemical reaction, available on demand. |

Lead, lead dioxide, sulfuric acid. |

Used in automotive, UPS, and solar applications. |

| Type |

Definition |

Construction |

Operation Principle |

Components |

Applications |

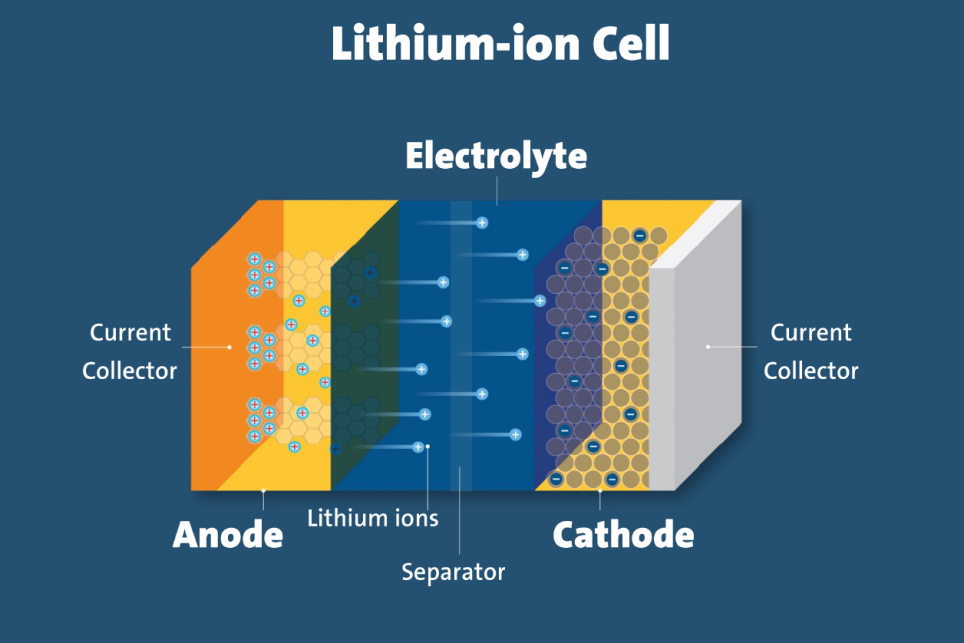

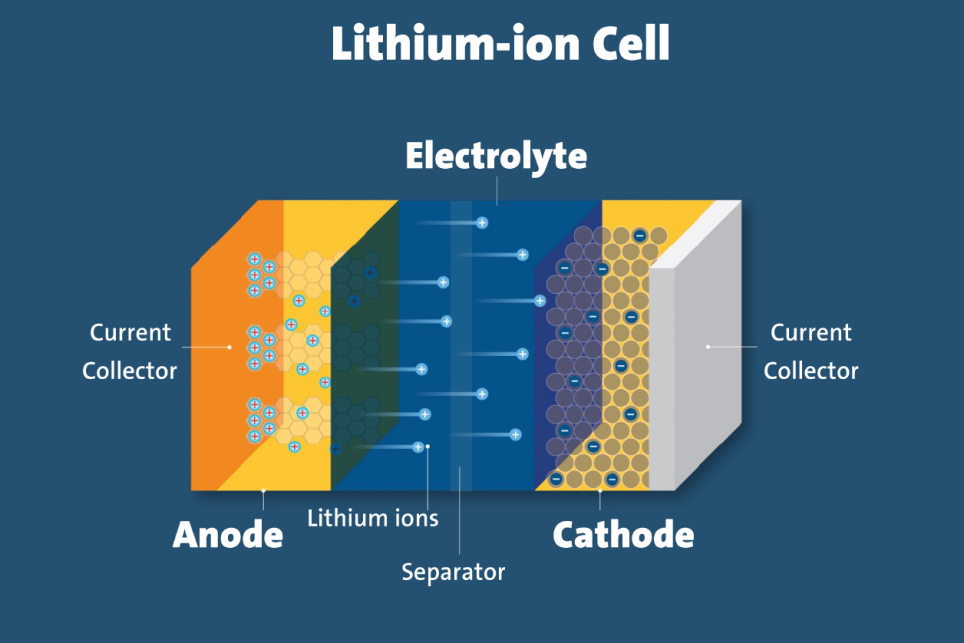

| Lithium-Ion Batteries |

Rechargeable batteries where lithium ions move between electrodes during discharge and charge. |

Cathode (lithium metal oxide), anode (carbon), electrolyte, separator. |

Lithium ions move through an organic solvent electrolyte between cathode and anode. |

Lithium metal oxides, carbon/graphite, organic solvent. |

Portable electronics, electric vehicles, renewable energy storage. |

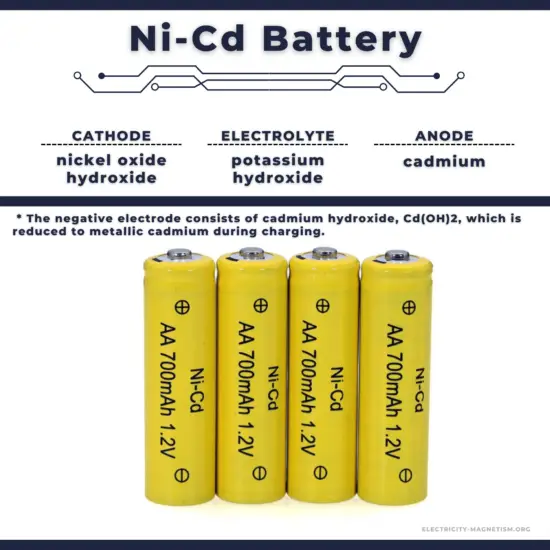

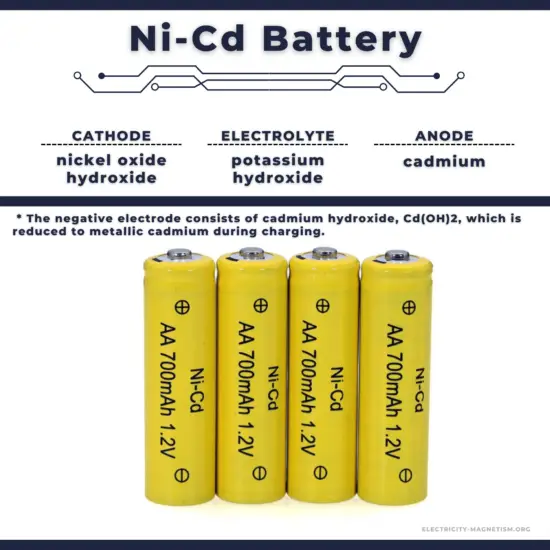

| Nickel-Cadmium Batteries |

Rechargeable batteries using nickel oxide hydroxide and metallic cadmium. |

Nickel and cadmium electrodes in an alkaline electrolyte. |

Oxidation-reduction reactions between cadmium and nickel compounds. |

Nickel oxide hydroxide, cadmium, alkaline electrolyte. |

Power tools, photography equipment, emergency lighting. |

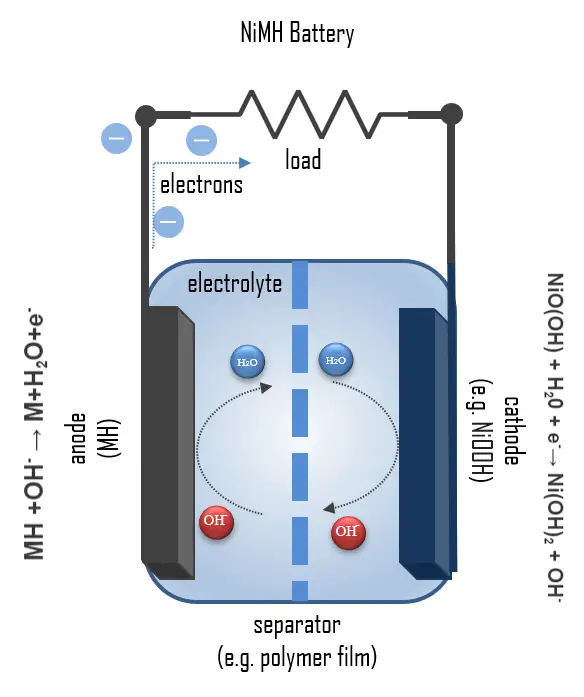

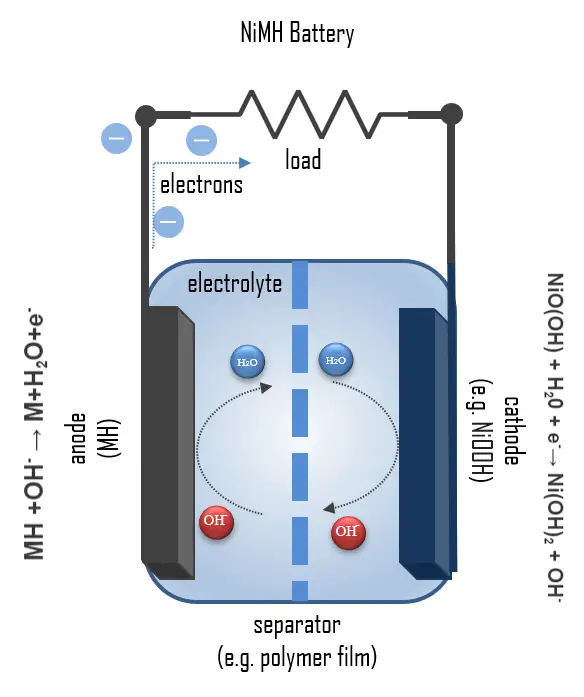

| Nickel-Metal Hydride Batteries |

Similar to nickel-cadmium but with a hydrogen-absorbing alloy replacing cadmium. |

Metal hydride negative electrode, nickel hydroxide positive electrode. |

Hydrogen ions move between electrodes, facilitating charge and discharge. |

Nickel hydroxide, metal hydride alloy, alkaline electrolyte. |

Hybrid vehicles, high-drain electronics, digital cameras. |

| Alkaline Batteries |

Primary batteries dependent on the reaction between zinc and manganese dioxide. |

Zinc powder anode, manganese dioxide cathode, alkaline electrolyte. |

Electrochemical reaction of zinc with manganese dioxide produces energy. |

Zinc, manganese dioxide, alkaline potassium hydroxide. |

Remote controls, flashlights, toys, and portable electronics. |

| Image |

Description |

|

This image illustrates the basic knowledge and classification of lead-acid batteries.

|

|

This image shows the structure of a lithium-ion cell, highlighting its components.

|

|

This image provides a composition breakdown of a nickel-cadmium (Ni-Cd) battery.

|

|

This image details the principle structure and material composition of a nickel-cadmium battery.

|

|

This image explains the principle of operation for a nickel-metal hydride (NiMH) battery.

|

|

This image highlights the design and structure of alkaline batteries.

|

|

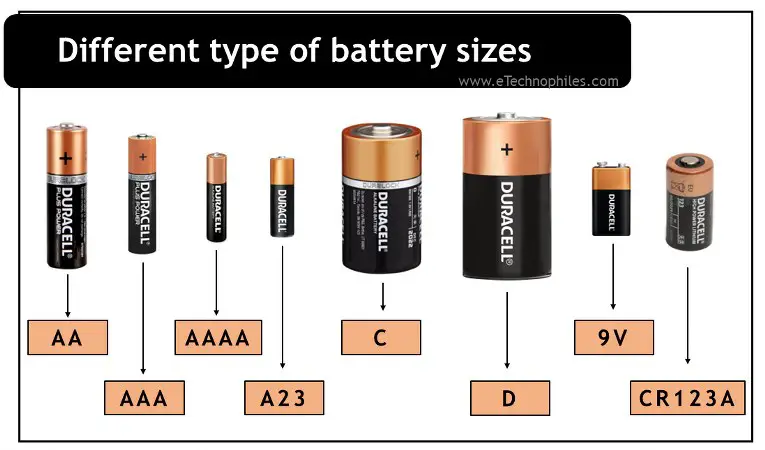

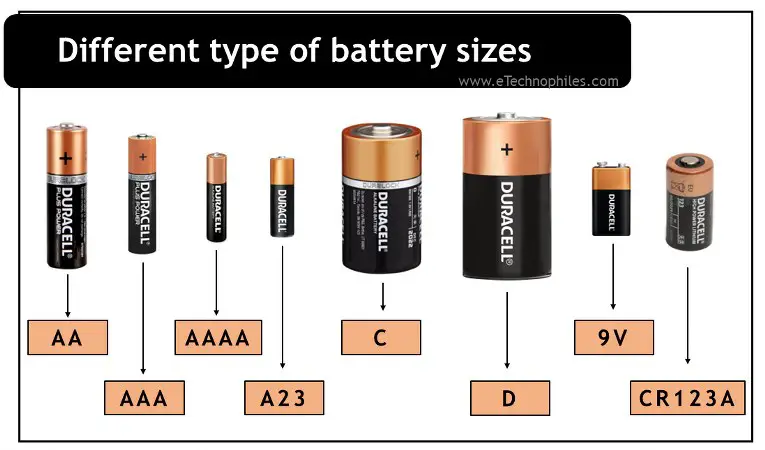

This image compares various battery sizes and their typical applications.

|